Basics of resin printers

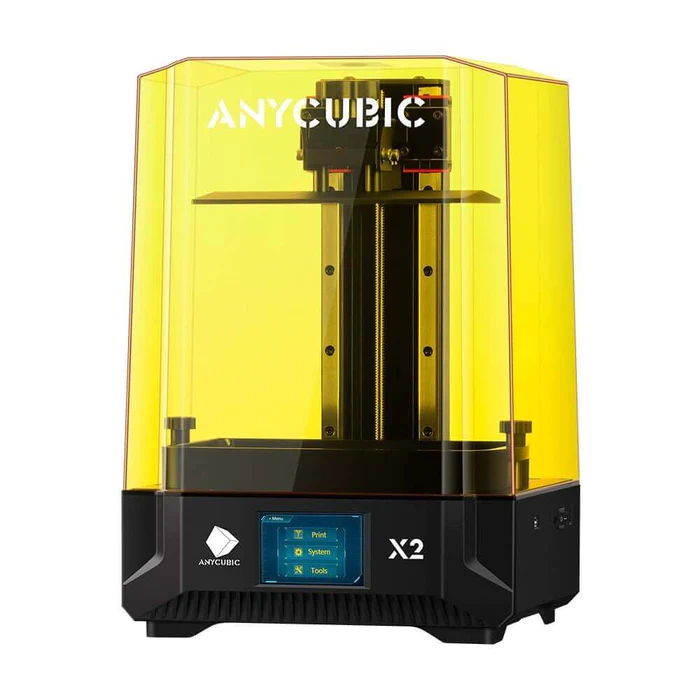

What are resin printers?

resin printers are considered a key technology in 3D printing. They use liquid resin that is hardened by light. This technique offers a high level of detail and a smooth surface of the printed objects. Complex shapes are created by hardening layer by layer. These printers are therefore ideal for models, jewelry or dentures. However, they are sensitive to UV light and require clean handling.

Comparison: Resin printer vs. SLA printer

Comparing resin and SLA printers is all about details. Both use UV light and resin. But there are differences. Resin printers are often cheaper to purchase. SLA printers, on the other hand, are characterized by high precision. Resin printers are suitable for hobby and small series. SLA printers are often found in the professional industry. The variety of materials is usually greater with SLA. Both techniques require post-processing and security measures. The choice depends on the purpose and budget.

Optimization of printing results with resin printers

Preparing for printing and choosing the right resin

To achieve optimal results with a resin printer, correct preparation is crucial. First, you should choose the right resin for the project. There are many types that differ in strength, flexibility and color. UV-curing resins are the most common choice. They require a certain exposure time for perfect curing. The printer must also be clean and calibrated. This especially applies to the build platform and the resin tank. Both should be free of dust and curing residues. An even and bubble-free resin layer ensures print quality. The ambient temperature also plays a role. Ideally it should be between 20°C and 25°C.

Fine-tuning of printing parameters for highest quality

In order to achieve perfect results, fine-tuning the printing parameters is essential. Each resin printer has specific settings that need to be adjusted. These include the exposure time, the layer height and the curing time. Careful adjustment of these parameters not only improves the level of detail but also reduces the risk of printing errors. Users should always follow the manufacturer's instructions and carry out test prints if necessary. Iterative adjustment and testing ultimately leads to the optimal configuration for high-quality prints.

Post-processing and curing of resin printed objects

The post-processing phase is crucial for quality. After an object has been made with a resin printer, there are a few steps that must be followed to achieve optimal results. Here is a quick guide:

- Clean: Remove excess resin with isopropyl alcohol.

- Smoothing: Use sandpaper to work on rough surfaces.

- Curing: Expose the object to UV light to fully cure it.

- Inspection: Check the print piece for defects and edit as necessary.

These steps ensure the longevity and functionality of the printed objects.

Advanced areas of application for resin printers in Germany

Use of resin printers in industry and research

resin printers are highly valued in the German sector. They are used in industry for prototypes, tools and end products. The high precision of resin printers makes them ideal for complex parts. In research, they help produce models. For example in medicine, where researchers recreate organs in 3D. This helps plan operations. Future technologies such as microfluidics also benefit from resin printing. This involves components the size of micrometers. Resin printers are very good for such fine structures.

Creative uses for resin printers in design and art

resin printers open up new horizons in the world of design and art. These advanced devices allow artists and designers to create complex, detailed objects with a precision that is difficult to achieve using conventional methods. Here are some creative uses for resin printers:

- Jewelry Design: Creation of unique and finely detailed pieces of jewelry.

- Sculptures: Creating complex sculptures with delicate textures and patterns.

- Architectural Models: Accurate printing of models for studies and presentations.

- Prototypes for product design: Quickly create prototypes to check form and function.

- Film and theater props: Realization of tailor-made and realistic props.

By using resin printersn in these fields, creative people can push the boundaries of their work and offer innovative solutions.

Future forecast: developments and trends in the area of resin printing technology

Resin printing technology is constantly evolving. Trends and developments are emerging in Germany that will shape the future of resin printers. We see that this technology is becoming increasingly important, especially for highly specialized applications. Here are some trends:

- Special resins with improved properties: Resins are coming onto the market that are even more resistant. These offer greater detail and better mechanical properties.

- Larger print formats: The demand for larger printers is increasing. They should be able to print large objects in one piece.

- Faster printing speeds: Research aims to reduce printing times. This improves productivity.

- Sustainable resin options: The development of more environmentally friendly resins is becoming increasingly important. These are biodegradable or recyclable.

This preview shows how resin printing could set new standards in industry and creative fields.